Maintaining your vehicle’s suspension is crucial for safe and comfortable driving. A well-functioning suspension system ensures optimal handling, braking, and ride quality. However, diagnosing suspension issues can be challenging for the average car owner. This guide simplifies the process by focusing on four common problems: worn shocks and struts, damaged ball joints, failing sway bars, and worn bushings. By understanding the visual cues and employing simple diagnostic techniques, you can identify these problems early, preventing costly repairs and ensuring your safety on the road.

We’ll explore each component systematically, providing clear explanations and practical steps to help you assess the condition of your vehicle’s suspension. Whether you’re a seasoned DIY enthusiast or a novice car owner, this guide will empower you to confidently diagnose potential issues and make informed decisions about necessary repairs or maintenance.

Identifying Worn-Out Shocks and Struts

Worn-out shocks and struts are a common cause of poor vehicle handling and ride comfort. Recognizing the signs of wear is crucial for maintaining safety and extending the lifespan of your vehicle. This section will guide you through identifying these issues visually and through simple tests.

Visual Inspection of Shocks and Struts

A visual inspection can often reveal signs of worn shocks and struts. Look for leaks of fluid around the shock or strut body, indicating a damaged seal. Damaged seals can also be seen as cracks or tears in the rubber boot surrounding the shock rod. Rust or corrosion on the shock body or mounting points is also a strong indicator of age and potential wear. Additionally, observe the condition of the shock’s or strut’s mounting hardware for any signs of looseness or damage. These visual cues can provide a strong indication of the component’s condition, although further testing is often necessary for confirmation.

Comparing Shock and Strut Wear Symptoms

The symptoms of worn shocks and struts can overlap, but some key differences exist. The following table summarizes these differences to aid in diagnosis.

| Symptom | Shock Wear | Strut Wear | Severity Level |

|---|---|---|---|

| Fluid Leaks | Visible fluid leakage around the shock body. | Visible fluid leakage around the strut body, often near the top mount. | High – indicates significant seal damage. |

| Damaged Seals/Boots | Cracks, tears, or significant wear in the rubber boot covering the shock rod. | Similar to shocks; cracks or tears in the rubber boot. | Medium to High – reduced protection from elements and potential for further damage. |

| Bouncing/Rebounding Issues | Excessive bouncing after compression; slow rebound. | Similar to shocks; excessive bouncing and slow return to normal position. | Medium to High – affects handling and braking. |

| Rust/Corrosion | Significant rust or corrosion on the shock body or mounting points. | Similar to shocks; rust or corrosion can weaken the structure and affect performance. | Low to Medium – depending on the extent of the damage. |

| Noise | Knocking or clunking sounds, especially over bumps. | Similar to shocks; noises indicate worn internal components or mounting issues. | Medium – points to internal damage or mounting problems. |

Bounce Test and Rebound Test Procedures

Performing a bounce test and a rebound test can help assess the functionality of your shocks and struts. These simple tests provide a quick evaluation of their damping capabilities.

These tests are crucial for determining the effectiveness of your vehicle’s shock absorbers and struts. A compromised system can severely impact handling and braking, so a thorough assessment is essential.

- Bounce Test: Push down firmly on each corner of the vehicle. A worn shock or strut will exhibit excessive bouncing and a slow return to its normal position. A healthy suspension will return to its normal position quickly and smoothly, with minimal oscillation.

- Rebound Test: Compress the suspension by pushing down on the vehicle’s bumper. Observe how quickly the suspension returns to its original position. A slow return indicates worn shocks or struts. The rate of return should be relatively consistent across all four corners of the vehicle.

Impact of Worn Shocks and Struts on Handling and Braking

Worn shocks and struts significantly compromise vehicle handling and braking performance. Reduced damping leads to increased body roll in corners, making the vehicle feel unstable and difficult to control. The extended stopping distance resulting from reduced tire contact with the road during braking is a serious safety concern. For example, a vehicle with worn shocks might require an additional 10-15 feet to stop completely compared to a vehicle with properly functioning suspension components at highway speeds. This increased stopping distance significantly increases the risk of accidents. Furthermore, uneven tire wear is a common consequence of worn suspension components, leading to premature tire replacement.

Diagnosing Worn Ball Joints

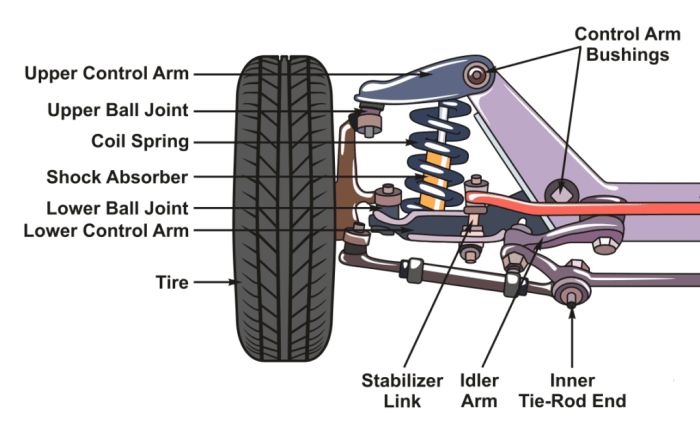

Ball joints are critical components of your vehicle’s suspension system, connecting the control arms to the steering knuckles. Their smooth operation is essential for safe and controlled steering. Worn ball joints can lead to dangerous handling characteristics and should be addressed promptly. This section will guide you through visually inspecting and testing your ball joints for wear.

Visual Inspection of Ball Joints

A visual inspection is the first step in diagnosing worn ball joints. Begin by carefully examining each ball joint for any obvious signs of damage. Look for grease leaks, cracks in the boot (the rubber covering protecting the joint), or any signs of corrosion. A healthy ball joint boot will be intact and free from tears or significant wear. A damaged boot allows contaminants to enter, leading to premature wear and failure.

Imagine two images side-by-side. The first depicts a healthy ball joint: the boot is smooth, intact, and evenly colored, with no visible cracks or tears. Grease is contained within the boot, and the metal components appear clean and free from rust. The second image shows a worn ball joint: the boot is torn or severely cracked, allowing grease to leak out. There might be visible rust or corrosion on the metal components, and the overall appearance suggests significant wear and tear. The boot’s integrity is compromised, leaving the joint vulnerable to damage.

Checking Ball Joint Movement with a Pry Bar

After a visual inspection, a more thorough check involves using a pry bar to assess the ball joint’s movement. This test helps detect excessive play, which indicates wear. Safety is paramount during this procedure; ensure the vehicle is securely supported on jack stands and the parking brake is engaged.

To perform this test, place the pry bar’s tip between the control arm and the steering knuckle, near the ball joint. Gently apply leverage to try and move the knuckle. A small amount of play is normal, but excessive movement—more than a few millimeters of up-and-down or side-to-side play—indicates a worn ball joint that needs replacing. Repeat this process for each ball joint. Excessive movement signifies a compromised joint and warrants immediate attention.

Consequences of Driving with Worn Ball Joints

Driving with worn ball joints is extremely dangerous. Excessive play can lead to unpredictable steering, making it difficult to maintain control, especially at higher speeds or during emergency maneuvers. This significantly increases the risk of accidents. Additionally, a failed ball joint can cause a sudden loss of steering control, resulting in a serious crash. A worn ball joint can also contribute to uneven tire wear, affecting vehicle handling and reducing tire lifespan. Therefore, addressing worn ball joints promptly is crucial for maintaining vehicle safety and reliability.

Recognizing Issues with Sway Bars and Bushings

Sway bars, also known as anti-roll bars, and their associated bushings are crucial components of your vehicle’s suspension system. They significantly impact handling and stability by reducing body roll during cornering and maneuvering. Inspecting these parts regularly can prevent potentially dangerous situations and costly repairs. Understanding the signs of wear and tear is key to maintaining a safe and responsive vehicle.

Sway bars and bushings work in tandem to control body roll. The sway bar itself is a metal bar that connects the suspension systems on opposite sides of the vehicle. Bushings are rubber components that act as dampeners, allowing for some movement while preventing excessive sway. Damage to either component will negatively affect your car’s handling.

Sway Bar Link and Bushing Inspection

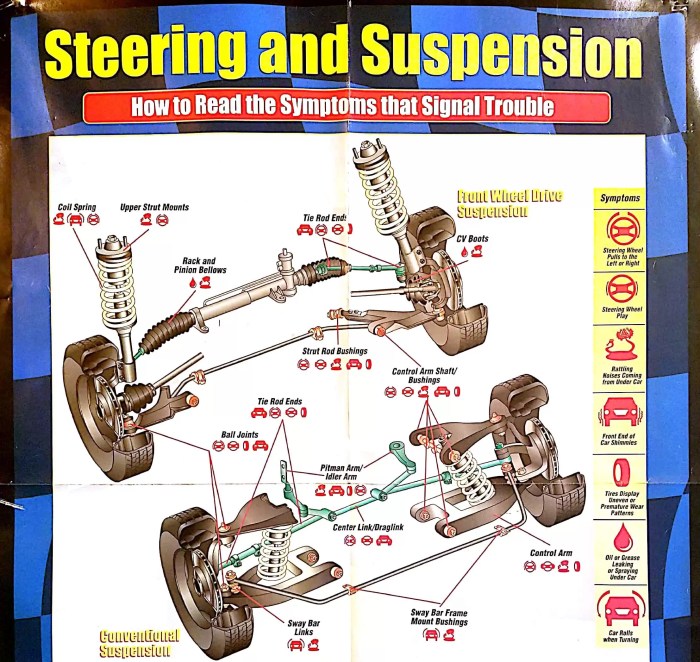

Visual inspection is the primary method for assessing the condition of sway bar links and bushings. Start by locating the sway bar, which is typically positioned near the bottom of the vehicle’s suspension system, connecting the left and right sides. The links connect the sway bar to the suspension control arms, and the bushings are located where the sway bar connects to the links and the chassis. Look for any signs of damage, including cracks, tears, or excessive wear. A visual guide is provided below to aid in locating these components.

Visual Guide to Sway Bar and Bushing Location

Imagine a typical car suspension system viewed from the side. The sway bar is a horizontal bar running across the underside of the vehicle, roughly midway between the front and rear wheels. On either end, you’ll see a link connecting the sway bar to the control arm of the suspension. These links are usually metal rods with ball joints at each end. At the points where the sway bar connects to the chassis and the links, you will find the bushings. These bushings are typically cylindrical rubber components that are compressed between the metal parts. They act as dampeners, absorbing vibrations and allowing for controlled movement.

Common Signs of Sway Bar and Bushing Wear

The following table summarizes common signs of wear and tear on sway bar links and bushings, along with their severity levels:

| Component | Sign of Wear | Severity | Impact |

|---|---|---|---|

| Sway Bar Links | Minor cracking in the rubber boot | Minor | Slight decrease in handling precision. |

| Sway Bar Links | Significant tearing in the rubber boot, exposed metal | Moderate | Noticeable decrease in handling, increased body roll. |

| Sway Bar Links | Complete failure of the ball joint | Severe | Loss of control, potentially dangerous. |

| Sway Bar Bushings | Minor cracking in the rubber | Minor | Slight increase in noise and vibration. |

| Sway Bar Bushings | Significant tearing or deformation of the rubber | Moderate | Increased body roll, noticeable handling issues. |

| Sway Bar Bushings | Complete bushing failure, metal-on-metal contact | Severe | Significant handling issues, loud knocking noises, potential for suspension failure. |

Impact of Faulty Sway Bars and Bushings on Vehicle Stability and Handling

Worn or damaged sway bars and bushings directly affect a vehicle’s handling and stability. Faulty bushings allow for excessive movement of the sway bar, resulting in increased body roll during cornering. This reduces control and increases the risk of skidding or loss of traction. Damaged sway bar links can lead to complete separation of the sway bar from the suspension system, significantly compromising handling and potentially causing a dangerous situation. In extreme cases, failure can lead to a loss of control, especially at higher speeds or during emergency maneuvers. Therefore, regular inspection and timely replacement of worn components are essential for maintaining safe and predictable vehicle handling.

Final Summary

Diagnosing car suspension problems effectively requires a methodical approach and a keen eye for detail. By systematically checking for visual signs of wear and tear, conducting simple tests like the bounce and rebound tests, and understanding the implications of each component’s failure, you can significantly improve your ability to maintain your vehicle’s safety and performance. Early detection of these common suspension issues can save you time, money, and potential accidents. Remember, regular inspection and proactive maintenance are key to ensuring a smooth and safe ride.