A malfunctioning sump pump can lead to costly water damage, transforming a minor inconvenience into a major headache. Understanding the subtle signs of impending failure is crucial for preventing such disasters. From unusual noises to reduced water flow, recognizing these indicators allows for timely intervention and avoids potentially devastating consequences to your home’s foundation and belongings.

This guide Artikels nine key warning signs that your sump pump is failing, providing practical advice on identifying problems early and taking proactive steps to ensure the continued protection of your property. We’ll cover everything from assessing its performance to conducting regular maintenance checks, empowering you to maintain a dry and safe basement.

Identifying Early Warning Signs

A failing sump pump often provides subtle clues before completely failing, leading to costly water damage. Recognizing these early warning signs is crucial for preventative maintenance and avoiding significant problems. Paying close attention to your sump pump’s operation can save you considerable time, money, and stress in the long run.

Unusual Noises from the Sump Pump

Unusual noises emanating from your sump pump are often the first indication of impending failure. A healthy sump pump typically operates quietly, with only a slight hum or whirring sound. However, loud clicking, grinding, or gurgling sounds may indicate mechanical issues, such as bearing wear, impeller damage, or motor problems. These sounds should not be ignored; they are often a precursor to complete pump failure. For example, a persistent grinding sound could indicate that the pump’s impeller is rubbing against the housing, causing friction and eventual failure.

Frequent Cycling of the Sump Pump

Frequent cycling refers to the sump pump turning on and off repeatedly in short intervals. While a certain degree of cycling is normal, depending on water inflow, excessive cycling suggests potential problems. If your sump pump is cycling more often than usual, especially when there hasn’t been significant rainfall or other sources of water inflow, it may indicate a clog in the discharge line, a failing float switch, or a weakening pump motor struggling to keep up with even small amounts of water. For instance, a pump cycling every few minutes when the basement is dry could signal a malfunctioning float switch.

Continuous Running of the Sump Pump

A sump pump running continuously, even without significant water accumulation, is a serious sign of trouble. This situation points to several possible issues. A clogged discharge line prevents water from being pumped out efficiently, causing the pump to work overtime. A faulty float switch, stuck in the “on” position, will also lead to continuous operation. A failing pump may struggle to move water, resulting in continuous operation even with small amounts of water present. For example, a heavy blockage in the discharge pipe might require manual intervention to clear the obstruction, allowing the pump to function correctly.

| Symptom | Description | Severity | Potential Cause |

|---|---|---|---|

| Unusual Noises | Loud clicking, grinding, gurgling, or other unusual sounds during operation. | Medium to High | Bearing wear, impeller damage, motor problems. |

| Frequent Cycling | Pump turns on and off repeatedly in short intervals, even without significant water inflow. | Medium | Clogged discharge line, failing float switch, weakening pump motor. |

| Continuous Running | Pump runs constantly, even without water accumulation in the sump pit. | High | Clogged discharge line, faulty float switch, failing pump motor. |

| Reduced Water Output | Pump struggles to remove water efficiently, leaving water in the sump pit. | Medium to High | Clogged impeller, worn-out pump components, low voltage. |

Analyzing Performance Issues

A sump pump’s performance directly impacts your basement’s dryness and overall structural integrity. Understanding how a failing pump manifests itself is crucial for timely intervention and preventing costly water damage. Analyzing performance issues involves observing the pump’s water flow, checking for pooling, and comparing its operation to that of a healthy pump.

Reduced water flow from the sump pump significantly compromises its ability to keep your basement dry. Even a slight decrease in pumping efficiency can lead to a gradual accumulation of water, potentially resulting in dampness, mold growth, and structural damage over time. The severity of the impact depends on the extent of the reduction and the frequency of rainfall or groundwater influx. A high-volume rainfall event could overwhelm a partially failing pump, leading to rapid flooding.

Water Pooling Around the Sump Pump

Water pooling around the sump pump is a clear indication of a potential problem. This pooling doesn’t necessarily mean the pump is completely failed; it often signifies reduced pumping capacity or a blockage in the discharge line. The water may be accumulating faster than the pump can remove it, leading to a visible pool. Regularly inspecting the area around the pump for standing water is a simple preventative measure.

Comparison of a Functioning and Failing Sump Pump

A comparison of a functioning sump pump against one nearing failure highlights the key differences in their performance characteristics.

- Water Removal Rate: A functioning pump efficiently removes water as it enters the sump pit, maintaining a consistently dry pit. A failing pump removes water slowly, leading to water accumulation in the pit.

- Cycling Frequency: A healthy pump cycles on and off as needed, responding to water level changes. A failing pump might cycle more frequently due to reduced pumping capacity or it might fail to activate even when the water level is high.

- Pump Noise: A functioning pump operates with a relatively quiet and consistent hum. A failing pump may exhibit unusual noises such as grinding, clicking, or gurgling, indicating mechanical issues.

- Discharge Flow: A functioning pump discharges water smoothly and forcefully through the discharge pipe. A failing pump may have a weak or intermittent discharge, or even a complete blockage.

Troubleshooting Flowchart

The following flowchart Artikels the steps to take when a sump pump exhibits performance issues.

[Diagram Description: The flowchart begins with a “Sump Pump Performance Issue?” diamond. A “Yes” branch leads to a rectangle labeled “Check for Water Pooling Around Pump”. From there, a “Yes” branch leads to a rectangle labeled “Clear any Blockages”. A “No” branch from “Check for Water Pooling Around Pump” leads to a rectangle labeled “Check Discharge Line for Blockages”. Both “Clear any Blockages” and “Check Discharge Line for Blockages” lead to a diamond labeled “Issue Resolved?”. A “Yes” branch leads to an end point labeled “Pump Functioning Properly”. A “No” branch leads to a rectangle labeled “Check Pump for Unusual Noises”. From there, a “Yes” branch leads to a rectangle labeled “Call a professional for repair or replacement”. A “No” branch from “Issue Resolved?” leads to a rectangle labeled “Check Power Supply”. From “Check Power Supply”, a “Yes” branch leads to a rectangle labeled “Call a professional for repair or replacement”. A “No” branch from “Check Power Supply” leads to a rectangle labeled “Check Float Switch Operation”. From “Check Float Switch Operation”, a “Yes” branch leads to a rectangle labeled “Call a professional for repair or replacement”. A “No” branch from “Check Float Switch Operation” leads to a rectangle labeled “Check Pump for Water Removal Rate”. From “Check Pump for Water Removal Rate”, a “Yes” branch leads to a rectangle labeled “Call a professional for repair or replacement”. A “No” branch from “Check Pump for Water Removal Rate” leads to a rectangle labeled “Pump Functioning Properly”. A “No” branch from the initial “Sump Pump Performance Issue?” diamond leads to an end point labeled “Pump Functioning Properly”.]

Assessing Physical Condition & Maintenance

A sump pump’s longevity and effective operation depend heavily on its physical condition and consistent maintenance. Neglecting these aspects can lead to premature failure and costly repairs, potentially resulting in significant water damage to your property. Regular inspections and preventative maintenance are crucial for ensuring your sump pump functions reliably when needed.

Regular maintenance involves more than just occasional checks. A proactive approach, including cleaning, visual inspections, and testing, can significantly extend the life of your sump pump and prevent unexpected breakdowns during crucial times, such as heavy rainfall or snowmelt. This section will guide you through the key aspects of assessing your sump pump’s physical condition and implementing a proper maintenance schedule.

Visual Inspection for Wear and Tear

Regular visual inspections can reveal potential problems before they escalate into major issues. Look for signs of wear and tear such as cracks in the pump housing, corrosion on metal components (especially around electrical connections), and loose wiring or connections. Pay close attention to the pump’s discharge pipe for any signs of leaks or damage. Cracks in the housing, for example, can allow water to seep into the motor, leading to short circuits and eventual failure. Corrosion can weaken structural integrity, potentially causing the pump to malfunction or fail entirely. Loose connections can lead to intermittent operation or complete power loss. Addressing these issues promptly can prevent more significant problems down the line.

Sump Pump Maintenance and Cleaning

The importance of regular sump pump maintenance cannot be overstated. A simple cleaning can remove sediment and debris that can hinder the pump’s operation or damage its components. This includes removing any accumulated sludge or debris from the sump basin itself. Regular cleaning helps ensure the pump operates efficiently and prevents premature wear. For example, a build-up of sediment can impede the pump’s ability to effectively remove water, leading to overloading and eventual burnout.

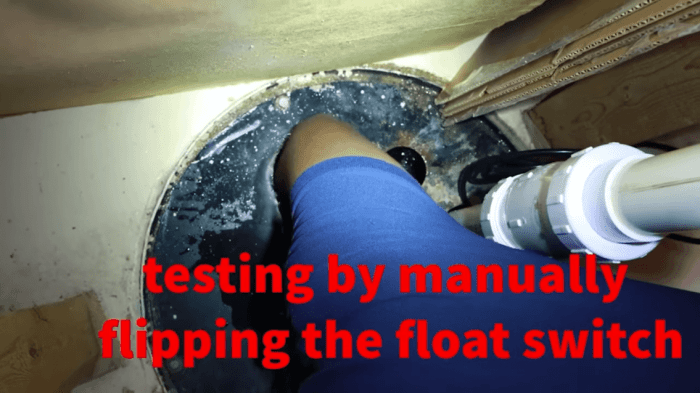

Float Switch Inspection

The float switch is a critical component that controls the pump’s activation. A properly functioning float switch will rise and fall smoothly with the water level, activating the pump when the water reaches a certain level and turning it off when the water recedes. A malfunctioning float switch might be stuck in the “on” or “off” position, causing the pump to run continuously or fail to activate when needed. A properly functioning float switch will move freely and smoothly, while a malfunctioning one might be jammed, corroded, or have a broken arm. Visually inspect the switch for any signs of damage, corrosion, or binding. Ensure it moves freely without resistance.

Sump Pump Maintenance Checklist

Regular maintenance is key to preventing sump pump failure. Here’s a checklist of tasks to perform:

- Inspect the sump pump for cracks, corrosion, and loose connections.

- Clean the sump basin of debris and sediment.

- Check the float switch for free movement and proper operation.

- Test the pump by manually activating it and observing its performance.

- Inspect the discharge pipe for clogs or leaks.

- Check the electrical connections for tightness and corrosion.

- Run the pump for a few minutes each month to ensure it’s functioning correctly.

- Consider professional maintenance every 1-2 years, depending on usage and environmental factors.

End of Discussion

Ignoring the early warning signs of a failing sump pump can lead to significant water damage and costly repairs. By proactively monitoring your sump pump for the nine signs discussed, and performing regular maintenance, you can significantly reduce the risk of basement flooding and protect your investment. Remember, a little preventative care goes a long way in ensuring the longevity and reliable performance of this critical home component.